- PRODUCT SPECIFICATIONS

- PACKAGING

CEWELD AA DUR NC is designed for multiple layer welding and offers amazing resistance against combinations of mineral wear and shock that makes it the ideal Hardfacing product for the tool joint and casing.

CEWELD AA DUR NC is designed for multiple layer welding and offers amazing resistance against combinations of mineral wear and shock that makes it the ideal Hardfacing product for the tool joint and casing.

Due to a high alloyed complex carbide combination this unique tool steel alloy offers extreme resistance against abrasion by minerals, all weld metal requires no buffer layer except on materials considered critical or in case of old hardsurfacing layers. The weld deposit can be aplied completely crack free in single and multilay overlay welding.

The weld metal is only machinable by grinding. Due to the production method (seamless copper coated flux cored wire) this wire can be stored for a long time without the risk of moisture pick up and has excellent feeding and welding properties.

Oil drilling tools, casings, crushing hammers, crusher jaws, stone crushers, crushing rollers etc.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 60 HRc |

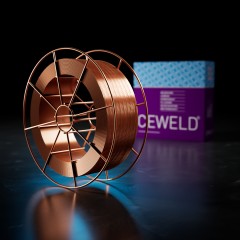

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 16 | 8720663424365 |