Rutile, basic or Cellulose Coated stick Electrodes, Different Types, Infinite Possibilities!

Choosing the right type of coated stick electrode is crucial and depends on various factors, including the material to be welded, the desired welding position, welding parameters, and the intended quality of the weld joint. In general, coated electrodes provide a convenient solution for a wide range of welding challenges, making them a commonly used choice in diverse industries where welding plays a significant role. There are different types of coating. Each has its own specific area of application.

Composition

Rutile-coated stick electrodes typically contain a mix of rutile (titanium dioxide), iron powder, cellulose, and other additives.

Characteristics

- Arc Stability: Rutile coatings offer excellent arc stability, making them well-suited for both beginner and experienced welders.

- Weld Appearance: They produce welds with a smooth, attractive bead appearance, making them suitable for applications where aesthetics matter.

- Ease of Use: Rutile stick electrodes are known for their ease of use, making them popular for a wide range of applications

Applications

Commonly used in automotive manufacturing, structural fabrication, and general welding tasks where a visually appealing weld finish is desired. For easy and smooth weldingproperties CEWELD E 6013 S is recommended.

CEWELD E 6013 S

CEWELD E 6013 S is a rutile cellulosic E 6013 welding electrode for stick SMAW welding of mild steels in all positions.

| AWS | A 5.1: E 6012 |

| EN ISO | 2560-A: E 38 0 RC 11 |

| F-NR | 2 |

| FM | 1 |

Composition

Basic-coated stick electrodes contain compounds like calcium carbonate, calcium fluoride, and may include deoxidizers like manganese and silicon.

Characteristics

- Penetration: Basic coatings provide deep penetration, making them suitable for welding thick materials and achieving strong, durable welds.

- Hydrogen Control: They have good resistance to hydrogen-induced cracking, making them suitable for welding high-strength steels.

- Contaminant Tolerance: Basic-coated stick electrodes can handle contaminants in the base metal, providing versatility in challenging welding environments.

Applications

Preferred for heavy construction, shipbuilding, and pipeline welding where high-strength steels and critical applications are common. For this application CEWELD E 7018-1 is recommended.

CEWELD E 7018-1

CEWELD E 7018-1 is a basic 7018-1 extra low hydrogen Stick electrode for SMAW stick welding (E 42 4 B Type).

| AWS | A 5.1: E 7018 |

| EN ISO | 2560-A: E 42 4 B 32 H5 |

| F-NR | 4 |

| FM | 1 |

Composition

Cellulose-coated stick electrodes contain cellulose as the primary constituent, often blended with rutile and mineral components.

Characteristics

- Deep Penetration: Cellulose coatings offer exceptionally deep penetration, making them suitable for welding thick sections.

- Spatter Formation: They tend to produce more spatter, requiring skilled welders for optimal control.

- Versatility: Suitable for all welding positions, cellulose-coated electrodes find application in various industries.

Applications

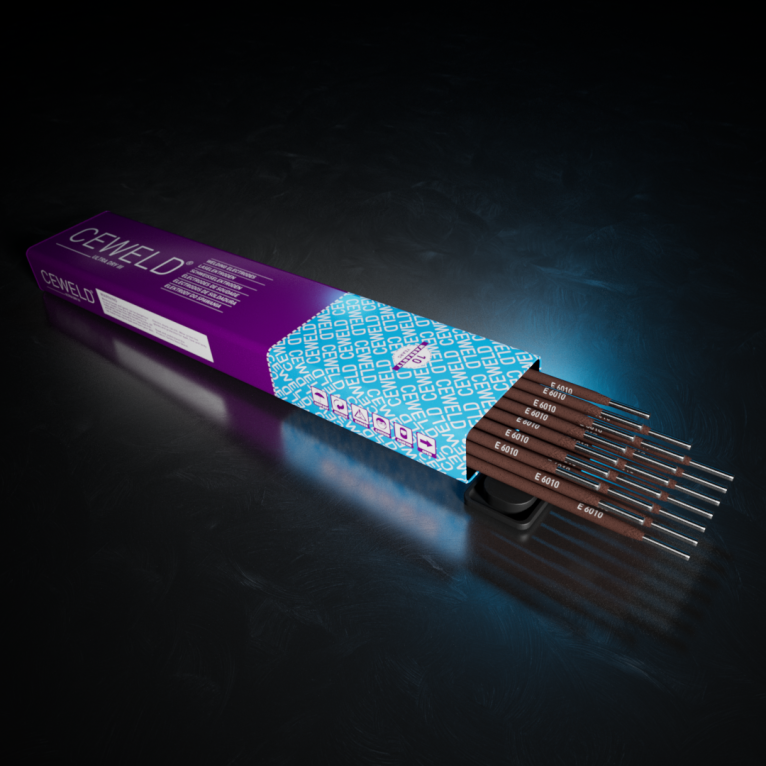

Widely used in pipeline welding, shipbuilding, and applications requiring deep penetration in thick materials. CEWELD E 6010 is very often used.

CEWELD E 6010

CEWELD E 6010 is a cellulosic electrode for SMAW vertical down welding

| AWS | A 5.1: E 7018 |

| EN ISO | 2560-A: E 42 4 B 32 H5 |

| F-NR | 4 |

| FM | 1 |

Composition

This coating includes iron oxide and iron powder as key components.

Characteristics

- Arc Stability: The presence of iron oxide and iron powder contributes to a stable arc, improving overall weld quality.

- Weld Appearance: Welds made with these electrodes often exhibit improved bead appearance.

- High recovery: The coating is very thick and usually amount to about 50% of the weight of the electrode, resulting in higher deposition efficiency.

Applications

Well suited for making fillet welds in the flat or horizontal position. The weld face is slightly convex to flat, with a very smooth surface and a very fine ripple. CEWELD E 7024 is the perfect example.

CEWELD E 7024 (200) and CEWELD E 7024 (200)

CEWELD E 7024 (200) is a high efficiency, rutile electrode with approximately 200% metal recovery.

| AWS | A 5.1: E 7024 |

| EN ISO | 2560-A: E 42 0 RR 73 |

| F-NR | 1 |

| FM | 1 |

CEWELD E 7024 (150) is a high efficiency, rutile electrode with approximately 150% metal recovery.

| AWS | A 5.1: E 7024 |

| EN ISO | 2560-A: E 42 0 RR 53 |

| F-NR | 1 |

| FM | 1 |