- PRODUCT SPECIFICATIONS

- PACKAGING

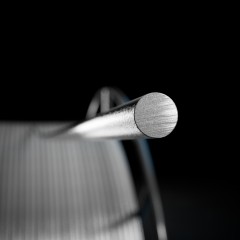

CEWELD® NiTi3 is developed for welding and cladding Nickel 200 and Nickel 201. This alloy is also suited for surfacing of steel. Dissimilar welding applications of filler metal NiTi3 include joining Nickel 200 and 201 to stainless steels, copper-nickel alloys, and Monel alloys. It is also used for joining Monel alloys and copper-nickel alloys to carbon steels, and for joining copper-nickel alloys to Inconel and Incoloy alloys.

CEWELD® NiTi3 is developed for welding and cladding Nickel 200 and Nickel 201. This alloy is also suited for surfacing of steel. Dissimilar welding applications of filler metal NiTi3 include joining Nickel 200 and 201 to stainless steels, copper-nickel alloys, and Monel alloys. It is also used for joining Monel alloys and copper-nickel alloys to carbon steels, and for joining copper-nickel alloys to Inconel and Incoloy alloys.

The reaction of titanium with carbon maintains a low level of free carbon and enables the filler metal to be used with Nickel 201. The weld metal has good corrosion resistance, particularly in alkali’s.

CEWELD® NiTi 3 is developed for welding and cladding Nickel 200 and Nickel 201. This alloy is also suited for surfacing of steel. Dissimilar welding applications of filler metal NiTi 3 include joining Nickel 200 and 201 to stainless steels, copper-nickel alloys, and Monel alloys. It is also used for joining Monel alloys and copper-nickel alloys to carbon steels, and for joining copper-nickel alloys to Inconel and Incoloy alloys. Type of alloys : Nickel 200 - Nickel 201

UNS Nr: N 02200 - N 02201

DIN 17742: Ni 99.6, Ni 99.2, LC-Ni99.6, LC-Ni99

2.4060 - 2.4061 - 2.4066- 2.4068

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness |

|---|---|---|---|---|---|

| RT | |||||

| As Welded | 200 | 420 | 30 | 120 | HRc |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663417695 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663417701 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663417725 |

| BS-300 | 15 | 8720663417718 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663417732 |