- PRODUCT SPECIFICATIONS

- PACKAGING

Boilers, tanks, agriculture, liquid storage tanks, food machinery, furniture.

Boilers, tanks, agriculture, liquid storage tanks, food machinery, furniture.

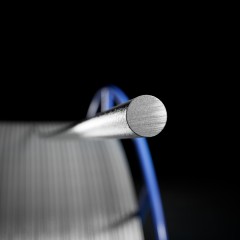

CEWELD® 308L has good general corrosion resistance. The alloy has a low carbon content, making it particularly recommended where there is a risk of intergranular corrosion.

ISO 15608: 8.1 Austenit ≤ 19 % Cr 9% Ni,TÜV 1000: Gr. 21 - 22 (29 max.350°C),

1.4000, 1.4301, 1,4306, 1.4307, 1.4308, 1.4311, 1.4312, 1.6900, 1.6901, 1.6902, 1.6903, 1.9606, 1.4541, 1.4546, 1.4550

X 6 Cr 13, X 5 CrNi 18 10, X 2 CrNi 19 11, X 5 CrNi 18 9, G-X 6 CrNi 18 9, X 12 CrNi 18 9, G-X 8 CrNi 18 10, X 6 CrNi 18 10, X 10 CrNiTi 18 10, X 5 CrNi 18 10

AISI 304, 304H, 312, 321H, 347, 347H,

UNS S30409, S32109, S34709, S30400, S32100, S34700

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness | ||

|---|---|---|---|---|---|---|---|

| RT | -60°C | -196°C | |||||

| As Welded | 480 | 630 | 37 | 170 | 150 | 75 | HRc |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663412492 |

| D-100 | 1 | 8720663412508 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663412515 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 15 | 8720663412522 |